A filter aid, by definition, is a solid particle agent that improves filtering efficiency by forming a porous, permeable, and rigid lattice structure—the filter cake—that holds solid particles while also assisting with flow control.

What is a Septum and How does it Interact with Filter Aid?

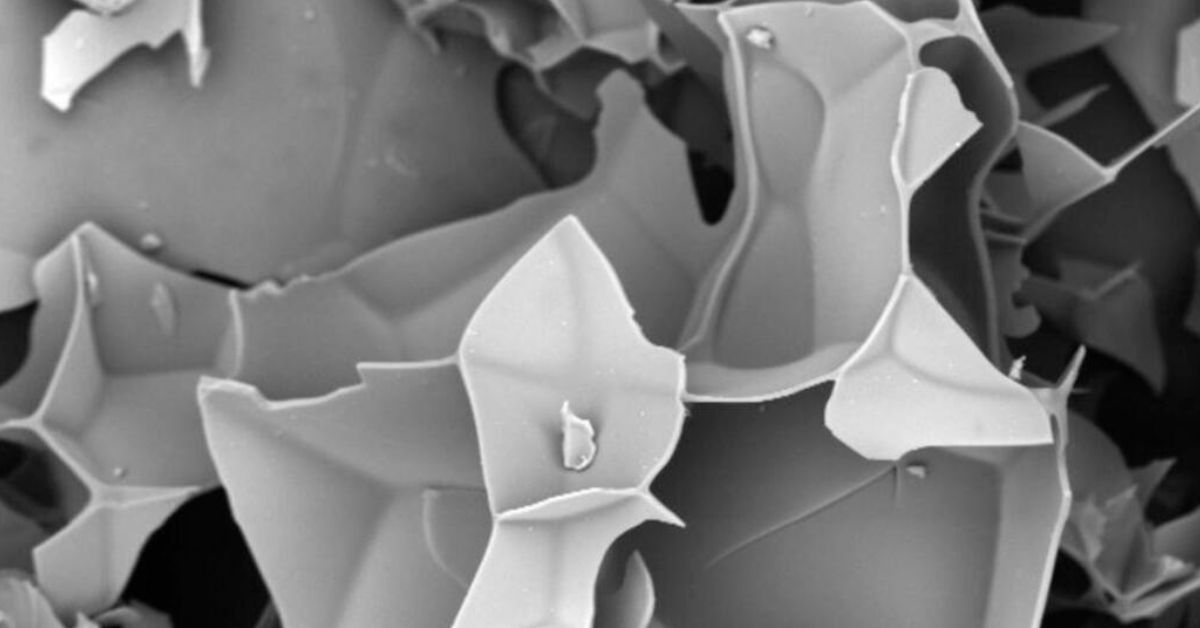

The septum, which is normally made of screen or fabric, acts primarily as a support for the filter cake. The filter aid produces a porous layer on the septum and serves as the filtering medium, trapping particles and keeping them from blinding the septum. Irregularly shaped particles interlace and overlay, leaving free spaces between the filter aid particles—billions of microscopically fine interstices. The apertures are so small that undesirable particulates are strained from the liquid, and the sheer quantity of openings compensates for their small size, resulting in high flow rates and spectacular clarity.

Advantages of Filter Aid

● Local supply—near the point of usage

● Specifically designed for the local application

● Short lead time

● Low Filter cake density.

● Permeability is really high.

● Cake breaking is reduced, and cake release is simplified.

● A wide range of attributes in terms of density and size are available.

● Provides cost effective Filtration

● Nature is sterile and inert.

● Simple disposal and safe handling

What are Filter Aids Used For?

Filter aids have the potential to serve as a precoat on the septum or as a body feed in the liquid. Filter aids can be put as a precoat as a thin coating over the filter before the suspension is poured into the apparatus.

The utilization of a precoat serves the purpose of preventing the entanglement of tiny suspension particles within the filter media, hence mitigating the increase in resistance. Additionally, it facilitates the removal of cake at the conclusion of the filtration process.

How is Filter Aid Used?

Typically, the thickness of the precoat ranges from 1.5 to 3.0 mm.

Therefore, it is necessary to utilize a quantity of wet filter aid ranging from 1.5 to 3 liters in order to effectively cover an area of approximately 1 square meter on the septal surface.

Following the precoat application process, a specific quantity of the filter assist substance can be integrated with the suspension prior to its introduction into the filter. The incorporation of filter aids enhances the permeability of the cake, diminishes its compressibility, and mitigates its resistance.

The addition of filter aids typically falls between the range of 0.01 – 4% by weight of the suspension. However, it is crucial to establish the optimal amount through experimentation. The filtering rate will be reduced when excessive quantities of filter aid are present.

Perlite filter aids necessitate the utilization of low shear agitation for the slurry. The uncontrolled breakdown of perlite can occur when it is subjected to severe shear and high concentrations.

How to Select The Best Perlite Filter Aid?

Perlite, a mineral characterized by its lightweight and porous nature, possesses remarkable filtration capabilities, rendering it a highly suitable selection for employment as a filter aid. The substance is derived from volcanic rock, which undergoes elevated temperatures to generate its distinctive composition.

The inherent lack of definite shape in perlite enables the formation of complicated networks including minuscule pores, which serve the purpose of effectively entrapping contaminants and solids, while simultaneously permitting the passage of liquids. The utilization of perlite as a filter aid results in an augmentation of filtration effectiveness by the creation of a pre-coat on the filter medium. This pre-coat serves to impede the occurrence of clogging and facilitates the enhancement of flow rates.

Amol Mine Chem is widely recognized as a respected producer of perlite products of superior quality. The company prides itself on providing customers with dependable and uniform filter aids suitable for a diverse range of industrial applications. Utilizing their extensive knowledge in the field of mining and processing perlite, they possess the capability to offer customized solutions that effectively address distinct filtration needs. Amol Mine Chem is a reliable source for fulfilling your perlite filter aid requirements. For the most optimal perlite as a filter aid, it is recommended to get in touch with Amol Mine Chem.