Perlite Filteraid

Mineral Insights

Perlite Filteraid

Perlite Filteraids manufactured by Amol Minechem Limited are marketed globally under the brand name “PERLFLOW™ ”.

- PERLFLOW™ Features

- PERLFLOW™ Specifications

- Usage & Application of PERLFLOW™

Perlite Filteraid - PERLFLOW™

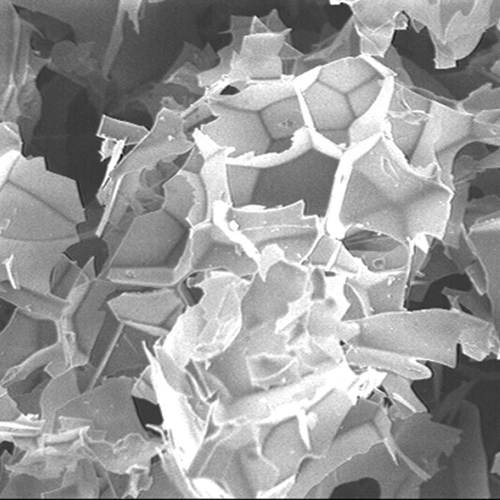

Perlite provides maximum flow rate and clearness by the help of its notchy and clamped thousands of microscopic channels (voids). Perlite doesn’t change filtered liquids taste, color and smell. Perlite is not melting for every degree of mineral and organic acids.

Cost Advantage - Perlite Filteraid PERLFLOW™

Perlite filteraid - PERLFLOW™ provide 20-50% more density advantage to users for effecting costs. Density of perlite filteraid - PERLFLOW™ are from 110 to 270 kg/m3 (7/17 lb/ft3). Dry density of perlite filteraid - PERLFLOW™ differs between 100 and 200 kg/m3 (6/12 lb/ft3). Experiences around various industries show that using perlite filteraid - PERLFLOW™ helping to decrease the cost of filteration-costs without making concessions on efficiency.

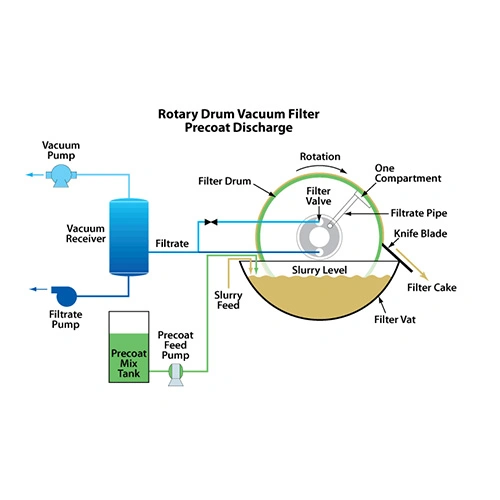

Usage In Standard Equipments

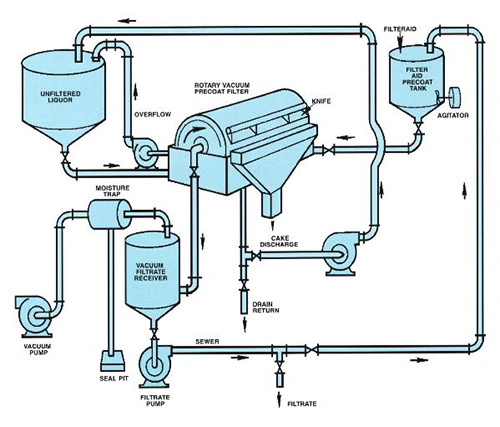

Perlite filteraid - Perlflow™ can be used with their pressurized and vacuumed equipments. If perlite filters are used in rotative vacuum filters; filter pulps can provide less cracks rather than other perlite filter aid. PERLFLOW™)’s exclusive processing system removes grit from the Filteraid thus making it as pure as possible. This also ensures longer life of filter equipment.

Higher Flow Rates

Perlite filteraid - Perlflow™ provide maximum clearness in highest level of flow rates. These are also applicable for liquids with higher density with syrup and gelatinized slurry. Efficiency can be increased by using perlite filteraid - Perlflow™.

Variation for Different Levels

Perlite filteraid - Perlflow™ is produced for usage in every industry and satisfying the needs of flow rates and clearness.

Easy Waste Discharge

It is not a hazardous waste and can be easily disposed off.

Increase Efficiency

Perlite filteraid - Perlflow™ provide maximum clearness in highest level of flow rates. These are also applicable for liquids with higher density with syrup and gelatinized slurry. Efficiency can be increased by using perlite filteraid - Perlflow™.

Approved by Industries

Perlite filteraid - Perlflow™ are used especially in drink, food and medicine industries for filtering liquids. Never effect taste,color or smell and approved.

Usage Of Filter Perlite Wastes As Animal Feeding Stuff

Another advantage of perlite filteraid that they can be used as animal feeding stuff in many countries. This can decrease the selling costs of filter wastes. It is not a hazardous waste and can be easily disposed off.

Availability

In last 30 years perlite filteraid are accepted in all industries. List below shows application areas of perlite filteraid but not all of them.

| Grade | Flow Ratio | Max. Filter Cake Density (Kg/m3) |

Mean Particle Size (Microns) |

|---|---|---|---|

| Perlflow™ 434 | 300 | 240 | 6 |

| Perlflow™ 474 | 650 | 232 | 8 |

| Perlflow™ 4104 | 900 | 240 | 10 |

| Perlflow™ 4154 | 1325 | 216 | 15 |

| Perlflow™ 4254 | 1700 Approx | 144 -208 | 18 Approx |

Usage & Application - Perlite Filteraid Perlflow™

PERLFLOW™ Perlite Filteraids are available in a full range of grades to meet the requirement of a wide variety of industrial applications from fast flow-rate to maximum clarity.

Solubility of PERLFLOW™ Perlite Filteraid is extremely low in inorganic and organic acids at both high and low temperatures. Solubility in alkali depends upon the kind of alkalies, the concentration and time and temperature of contact.

PERLFLOW™ Perlite Filteraids can filter out particles less than 1.0 micron in size.

Perlflow™ Perlite Filteraids Are Used As:

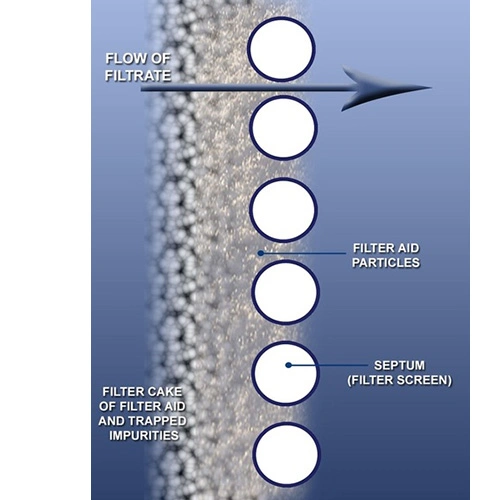

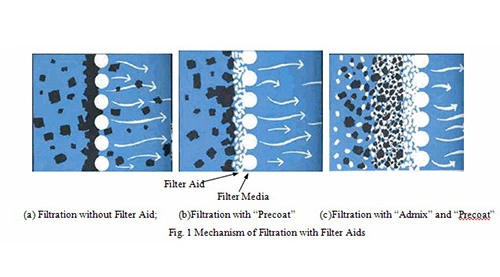

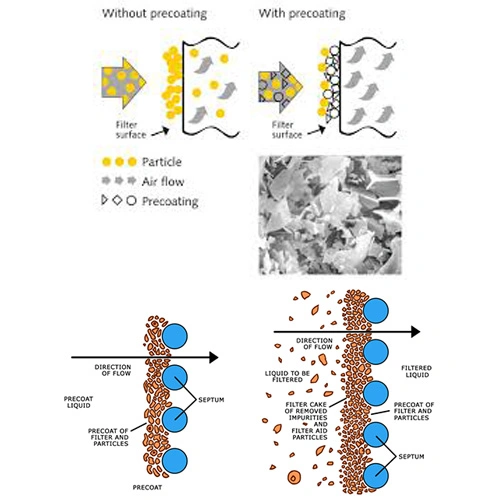

Precoat: The liquid to be filtered is allowed to flow through a cake of Filteraid.

Body Feed: Filteraid itself is added to the liquid to be filtered.

PERLFLOW™ Perlite Filteraid is used on various kind of filter equipment. PERLFLOW™ Perlite Filteraid is excellent for use in both pressure and vacuum filter equipment. Some of the common filter equipment used are:

- Rotary Vacuum Drum Filters

- Filter Press

- Vertical Tank Filter

- Tube or Candle Filter

- Pressure Leaf Filter

- Horizontal Tank – Rotating Leaf Filter, etc.

A selection criterion of Filter Equipment varies on the type of application, and depends on:

(a) The type and nature of liquid to be filtered and

(b) Quantity and the level of solid impurities.

Common Areas Of Usage / Application Industry-Wise

a) In food industry

- Filtration of beer, wine and liquor

- Filtration of vegetable oils

- Filtering of fruit juice

- Filtering of sugar juice

- Filtering of sweet corn (glucose/dextrose production)

b) Medicine and Chemical Industry

- Filtration of antibiotics

- Filtration of pectin

- Filtration of soda ash solution

- Filtration of citric acid

- Sodium silicate (water glass) filtration

- Sulfuric acid filtration

- Uranium filtration

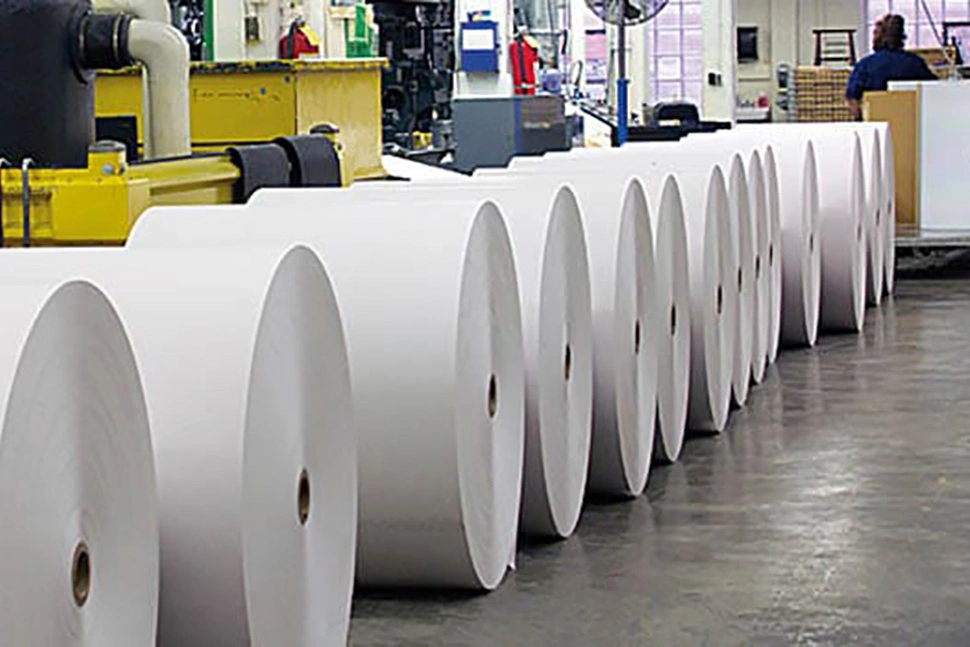

- Filtration in paper industry (white water)

- Flock filtration (aluminum hydroxide and flocculation procedures)

- Filtration of paints

- Filtration of phosphoric acids

c) Other filtration procedures

- Machine oils (regeneration of machine oils)

- Filtration of drinkable water

- Filtration of swimming pools

- Filtration of waste water cleaning