Thermal Insulation

Precision Insulation

Thermal Insulation

PERLITEMP is high temperature insulation, precision moulded into pipe and block shapes. Its principal ingredient- Expanded Perlite is one of the best of all the known naturally occurring Insulating materials. Its characteristic structure consists of millions off vitrified air cells. Through a proprietary process, these particles are bonded together with special inorganic binders and reinforcing fibers, moulded baked. Perlitemp conforms to ASTM C-610 Standard.

- PERLITEMP® Advantages

- PERLITEMP® Specifications

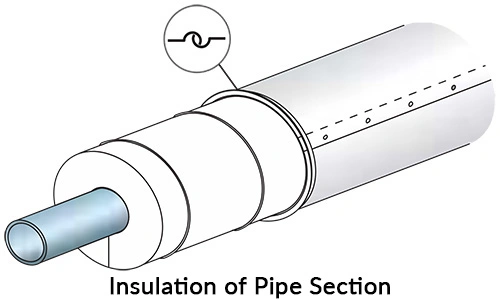

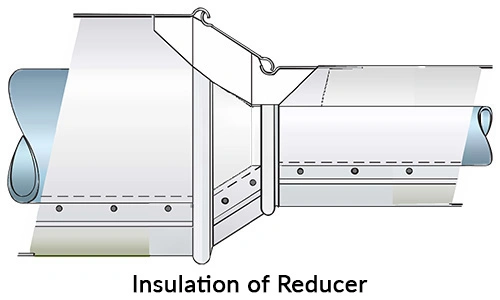

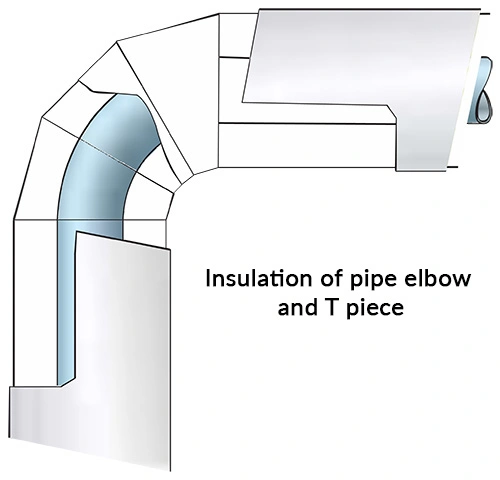

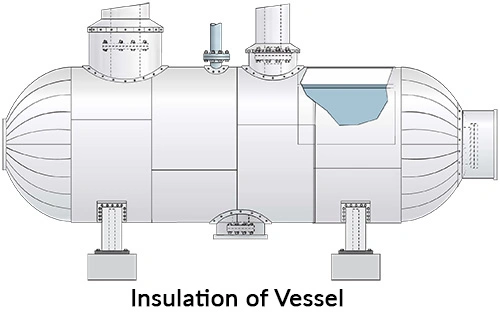

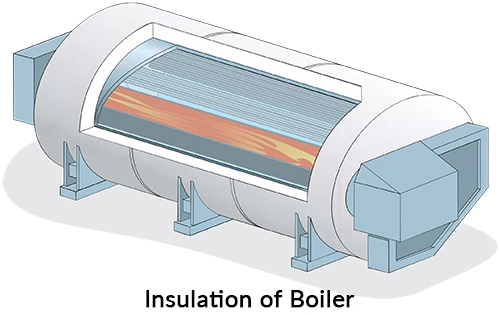

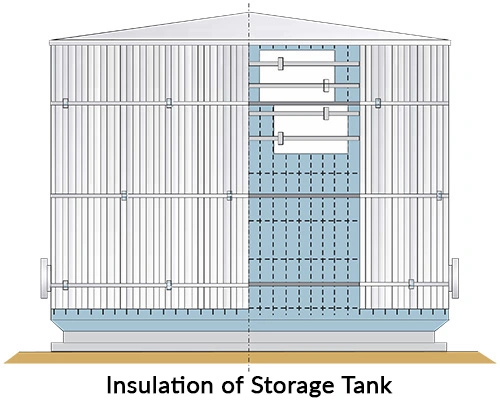

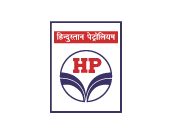

- PERLITEMP® Installation Examples

- Clients

Advantages of PERLITEMP®

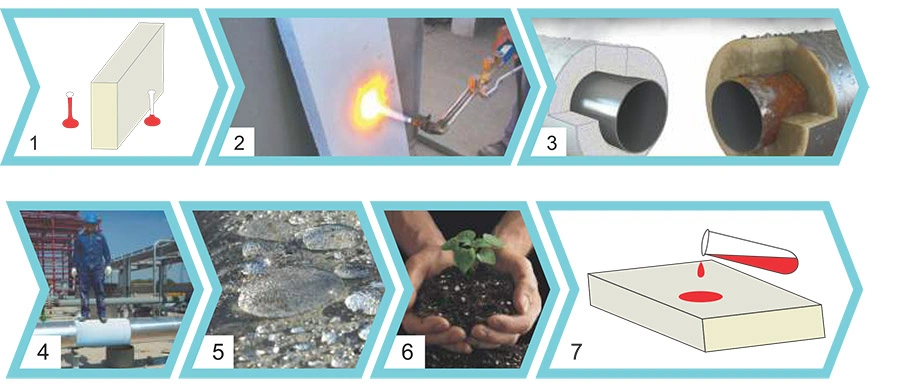

- Low Conductivity: Thermal conductivity of PERLITEMP® is low because of its principle ingredient being expanded perlite. Due to low thermal conductivity heat loss can be drastically reduced. Thermal conductivity can vary by temperature and density of the material. Thermal conductivity of PERLITEMP® is 0.062 W/Mk @25o c.

- Fire Resistance: PERLITEMP® has the property to resist fire as there is no Hydro-carbon in compound. So, in case of fire accident in plant, it can protect the pipeline and equipments. Sometimes it can be used in oil or gas storage tank for fire protection. It does not generate any toxic or any other smoke in case of direct contact with flame.

- Non-Corrosive: Due to extreme water repellant nature of perlite insulation, water cannot pass through. So that the material under the insulation can be protected against corrosion.

- Good Compressive Strength (Withstand foot traffic): Molded expanded perlite has high mechanical strength. Due to this nature it retains its shape long life. It is easy to climb on the insulation for any maintenance work without fear of damage.

- Water Repellant: The extremely water repellant nature of PERLITEMP® insulation retains the low thermal conductivity even when there is water ingress into system. Other insulation materials like calcium silicate, mineral wool and rock wool are known to have high water absorption resulting in a loss of insulation property.

- Environmental Friendly, Easy disposal as landfill: The main content of perlite is silica, so it can be safely used for landfill without causing any damage to the environment. Due to this unique property of perlite, it can also be used for Horticulture and Agriculture.

- Acid and Alkali Resistance: PERLITEMP® has a high resistance to concentrated acid such as Sulphuric Hydrochloric Acid and Nitric Acid. It is entirely free from acid erosion.

Additional Characteristics:

- Asbestos free

- Very low chlorine content: 8PPM

- Is a Natural Volcanic Glass with great availability in nature

- Has no impact on humans and does not cause irritation

- Does not emit toxic gases when exposed to heat i.e. fire etc.

- Recoverable and reusable

| Property | Test Method | ASTM Standard | We Offer |

|---|---|---|---|

| Density | ASTM C302/303 | 240 Kg/Cu.M. (Maximum) |

192-224 Kg/ Cu.M. |

| Moisture content | ASTM C610 | Max 10% by Weight | *3.5% by weight |

| Flexural Strength | ASTM C203 | 310 KN/Sq.M (minimum)(Block only) |

340 KN/Sq.M |

| Compressive Strength | ASTM C165 | 483 KN/ Sq.M-5% Compression(Block only) |

540 KN/ Sq.M |

| Linear Shrinkage | ASTM C356 | after 24 hours at 650oC Length 2%, Width 2% Thickness 8% |

PASS |

| Surface Burning characteristics | ASTM E84 | Flame Spreade-0 Smoke Developed-5 |

Flame Spreade-0 Smoke Developed-0 |

| Stress corrosion cracking of austenitic stainless steel | ASTM C692 | PASS | PASS |

| Water absorption after heat aging and 48 hours water immersion | ASTM C610 | 50% by weight | *33.2% by weight |

| Hot surface performance | ASTM C411 | PASS | PASS |

| Weight loss by tumbling | ASTM C421 | 70% | 62.8% |

| 1. Blocks | ||

|---|---|---|

| Standard Size | 900 ×500 mm |

|

| Standard Thickness | 25,30,38,50,64,75,88,100 mm | |

| 2. Pipe Coverings (Half Section) | ||

|---|---|---|

| Standard Size | 15, 20, 25, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300 mm NB |

|

| Standard Length | 914 mm | |

| Standard Thickness | 25,38,50,64,75,88,100 mm | |